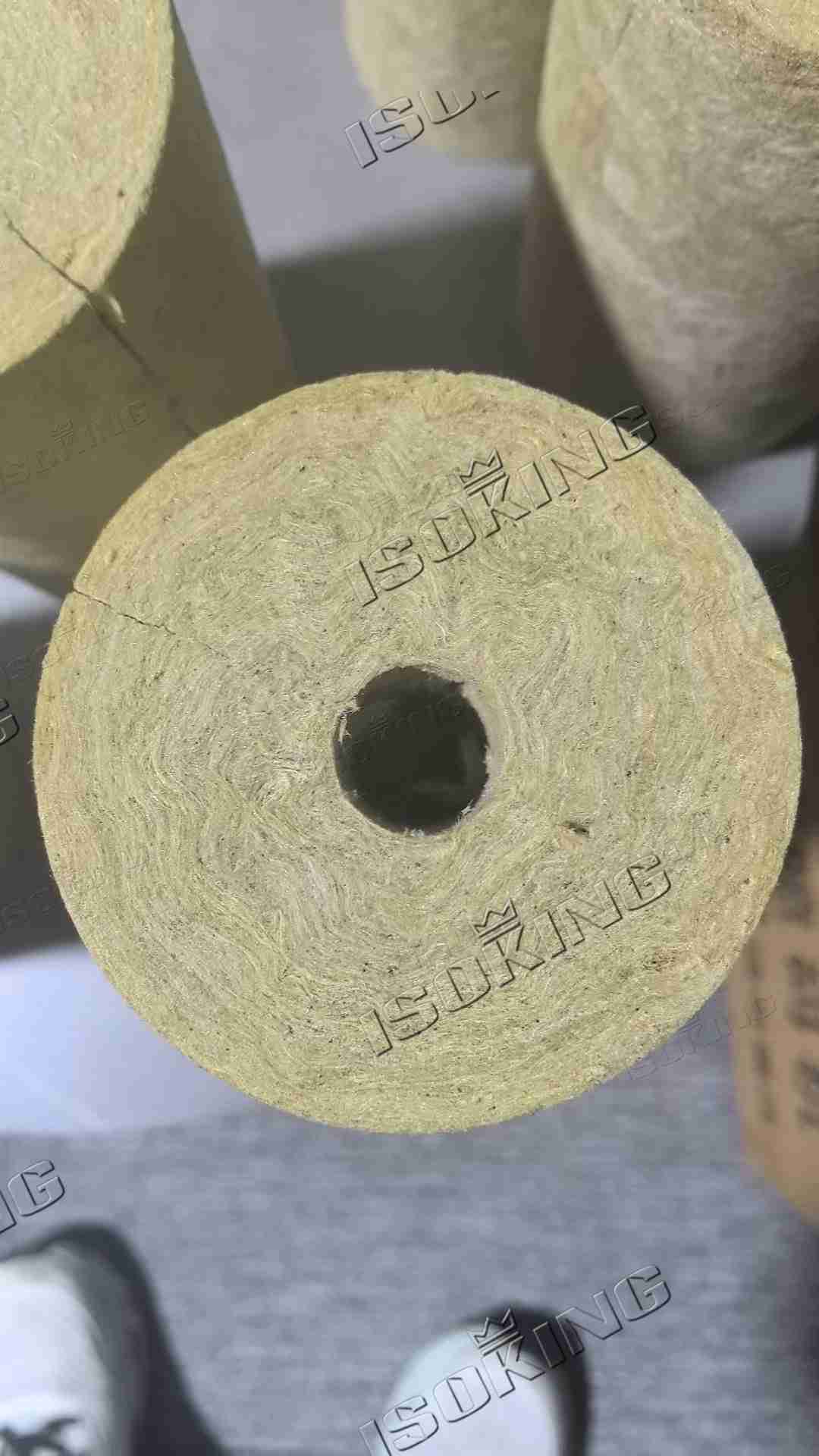

ISOKING Rock Wool Pipe

Inner Diameter:22mm-820mm

Thickness:25-200mm

Length:1m

Density:80-120kg/m³

MOQ-1*40HQ Container

ISOKING rock wool pipe comes with a highly adaptable selection of specifications, fully customizable to meet the insulation demands of different pipeline systems. We offer varied options in diameter, thickness and density, which can be precisely matched to both standard and custom pipeline sizes across diverse industrial sectors. Each batch of our rock wool pipe is subject to rigorous quality inspection procedures and adheres to strict international standards. This ensures consistent thermal insulation, strong fire resistance and long-lasting durability, making our product a solid, trustworthy option for all types of pipeline insulation projects.

| Inner Diameter(mm) | Thickness(mm) | Length(m) | Density(kg/m³) |

| 22-820 | 25-200 | 1 | 80-120 |

ISOKING rock wool pipe boasts broad applicability across multiple scenarios, delivering reliable insulation, fire protection and noise reduction for pipeline systems:

a. Heavy industrial manufacturing pipelines

Suitable for thermal insulation and fire protection of high-temperature fluid pipelines in steel mills, smelting plants and foundries, resisting extreme temperature fluctuations and preventing heat loss to improve production efficiency.

b. Oil and gas transmission pipelines

Ideal for onshore and offshore oil and gas gathering and transportation pipelines, effectively isolating high temperatures, resisting corrosion from oil and gas media, and ensuring the safe and stable operation of long-distance transmission systems.

c. Industrial boiler and steam pipelines

Applied to boiler outlet pipelines and high-pressure steam transmission pipelines in thermal power plants and industrial workshops, reducing heat dissipation, lowering energy consumption and meeting strict industrial fire safety standards.

a. Outstanding fire resistance

Non-combustible and flame-retardant, conforming to international fire safety standards. It can effectively inhibit flame spread and withstand high-temperature impacts, providing a solid safety barrier for industrial and construction pipelines.

b. High-efficiency thermal insulation

Low thermal conductivity enables excellent heat preservation and cold insulation effects. It reduces heat loss in high-temperature fluid pipelines and cold loss in low-temperature systems, helping to cut down energy consumption for temperature control.

c. Strong environmental adaptability

Resists moisture, salt spray corrosion and chemical erosion. It maintains stable performance in harsh working environments such as high humidity, marine salt fog and chemical workshops, with a long service life.

d. Easy construction & customization

Lightweight and easy to cut and install, it can be tailored into different diameters, thicknesses and densities according to the size of standard or non-standard pipelines, adapting to diverse project needs.